Crash Rated Explained: Standards, Testing, and Real Uses

Crash rated means a bollard or barrier has passed a full-scale vehicle impact test under a recognized standard, proving it can stop a real vehicle at a defined speed and weight. These systems deliver measured, documented performance not assumptions making them essential for perimeter security at high-risk sites.

Why This Really Matters

Think of perimeter security like a seatbelt. The crash rating is your crash test – it’s the difference between hoping something works and knowing it does.

What “Crash Rated” Actually Means

Here’s the truth: crash rated is a performance classification you only earn after driving real vehicles into your barrier under controlled conditions. No simulations. No estimates. Just physics.

The test records everything:

- Vehicle mass and type

- Impact speed and angle

- Penetration distance beyond the barrier line

If it hasn’t been physically tested and certified, it isn’t crash rated. Period.

The Standards That Matter

PAS 68 Rating: Where It All Started

The UK-developed PAS 68 rating established how hostile vehicle mitigation systems should be tested. This standard created a common language – encoding vehicle type, speed, angle, and measured penetration, so consultants, authorities, and insurers could finally speak the same dialect.

ISO 22343: The Global Evolution

To harmonize testing worldwide, PAS 68 evolved into IWA 14, and today we use ISO 22343: as the internationally recognized framework. This matters enormously in multinational projects where clarity isn’t optional.

We’ve worked across Abu Dhabi, Dubai, and the wider Middle East long enough to see what happens when corners get cut. A barrier that looks impressive but hasn’t been tested? That’s like a door with a painted lock. It might deter someone, but it won’t stop a determined vehicle attack. This is exactly why crash rating exists and why we back every claim with actual data.

Why standards change everything: They replace guesswork with repeatable, auditable proof. When a system is specified to a standard, everyone knows exactly what “good” looks like.

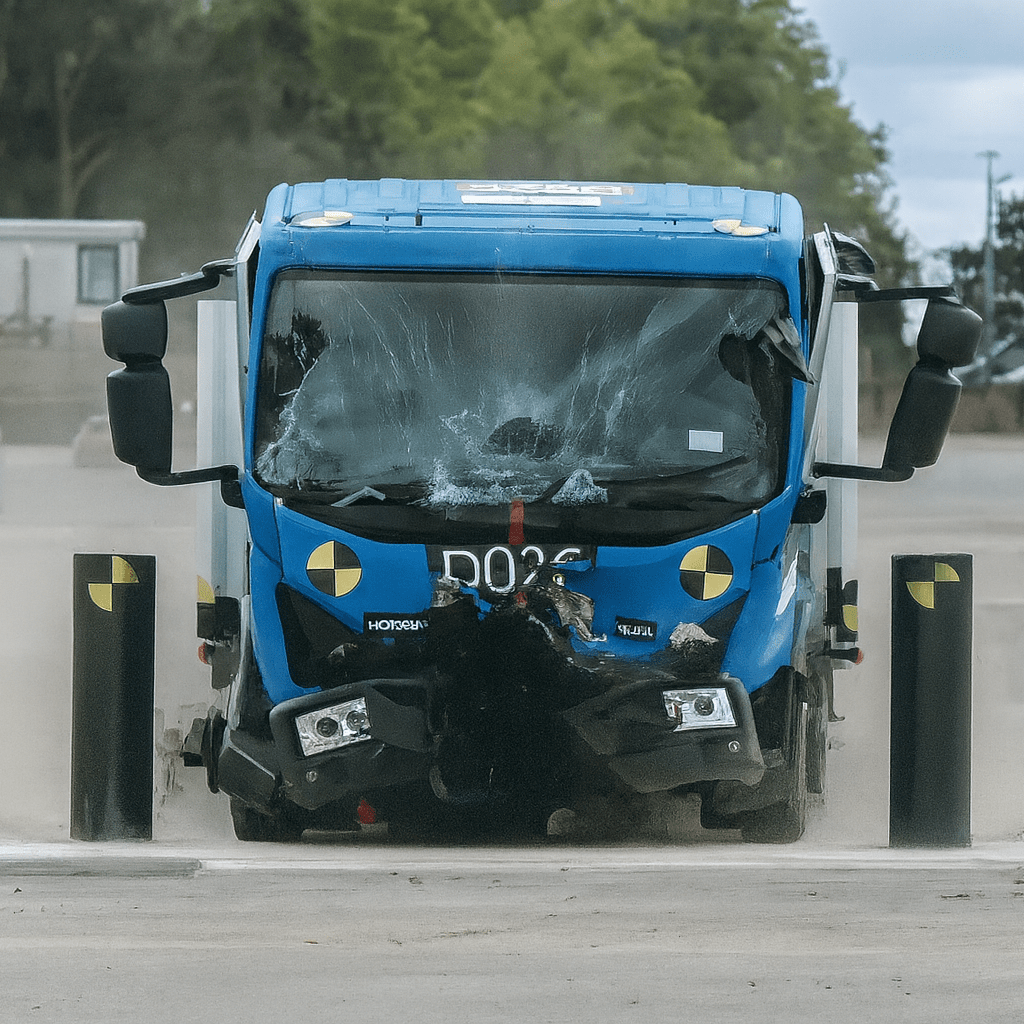

How Crash Rated Bollards Are Actually Tested

Let’s walk through what happens at a test facility:

- Select the threat vehicle (sedan, pickup, or medium truck)

- Set the speed and angle per the standard requirements

- Impact the barrier with a real vehicle not a computer model

- Measure penetration to see how far the vehicle travels past the barrier

- Document everything in a formal rating used for compliance

This is why crash rated systems earn trust: they’re tested the hard way, with real consequences on the line.

Crash Rated vs. “Heavy Duty” Bollards

Not all bollards are created equal. Here’s what separates proven protection from wishful thinking:

| Feature | Crash Rated Bollards | “Heavy-Duty” (Unrated) |

|---|---|---|

| Real vehicle impact test | ✅ Yes | ❌ No |

| Recognized standard | ✅ PAS 68 / ISO | ❌ None |

| Measured penetration | ✅ Documented | ❌ Unknown |

| Auditor acceptance | ✅ High | ❌ Low |

| High-risk site suitability | ✅ Yes | ⚠️ Risky |

We’ve seen too many projects fail audits because someone chose “industrial-looking” over “actually tested.”

Where We Install Crash Rated Protection

Our crash rated systems protect sites where failure simply isn’t an option:

Airports and transport hubs: Terminal frontages and drop-off zones where crowds gather

Government facilities: Diplomatic sites requiring controlled access with discreet standoff

Energy infrastructure: Oil and gas facilities, substations, and power plants across the region

Data centers: Protecting critical uptime from vehicle intrusion threats

Public spaces: Stadiums, waterfronts, and civic plazas where people should feel safe

In every case, the goal is identical: stop the vehicle before it reaches people or critical assets.

Why We Only Work With Proven Manufacturers

Here’s something most people miss: a crash rating only stays valid if the installed system matches the tested one exactly. This is where projects often stumble badly.

When we partner with manufacturers, you get:

- Authentic test reports backed by the actual manufacturer

- Exact installation requirements tied directly to certification

- Engineering support throughout design and construction

- Lifecycle guidance for inspection and maintenance

This is why we’ve built our reputation on manufacturer partnerships, not reseller relationships. When your security is on the line, the chain of accountability matters.

How We Approach Projects Across the Middle East

At Frontier Pitts Middle East, we combine manufacturer-tested systems with deep regional expertise. We’ve been delivering hostile vehicle mitigation solutions across Abu Dhabi, Dubai, and beyond because we understand what’s at stake.

What makes our approach different:

We provide access to fully certified crash rated bollards and barriers that meet PAS 68 rating and ISO standards. Our portfolio includes proven installations at airports, government facilities, and critical infrastructure throughout the region.

More importantly, we offer engineering guidance that preserves certification after installation—because a barrier that’s installed incorrectly is essentially unrated. We also understand regional codes, climate challenges, and site-specific constraints that can make or break a security project in the Middle East.

We don’t just sell barriers. We deliver defensible compliance you can document for auditors and insurers.

Choosing the Right Rating for Your Site

The right crash rating isn’t about “strongest possible” – it’s about fit-for-risk. Here’s our practical checklist:

- Identify the likely vehicle threat and approach speed

- Select the required standard (ISO or legacy PAS 68 rating)

- Define maximum allowable penetration based on your standoff space

- Confirm foundations and spacing match the tested configuration

- Document everything for authority approvals and insurance requirements

Think of it like choosing footwear: you want the right option for the terrain, not steel-toed boots for every occasion.

Integrating Protection With Design

Modern perimeter security blends safety with aesthetics and operational flow:

- Fixed or retractable bollards for managing traffic patterns

- Architectural finishes that harmonize with public spaces

- Integration with access control and CCTV systems

- Maintenance plans that keep performance audit-ready

Done right, crash rated protection fades into the background until the moment it’s needed.

Common Questions We Hear

Are crash rated bollards always visible? No. Many of our systems are discreet, architectural, or retractable designed to blend into public spaces while maintaining full certified performance.

Is PAS 68 rating still acceptable now that ISO exists? Yes. Many projects still specify PAS 68 rating, and it remains widely accepted. However, ISO 22343 is now the current international reference. Always follow your local authority requirements.

Can installation affect the rating? Absolutely. Foundations, spacing, and alignment must match the tested configuration exactly, or certification becomes invalid. This is why we emphasize installation support.

Do crash rated systems need maintenance? Yes. Regular inspection ensures alignment, fixings, and finishes remain compliant with the tested system over time.

The Bottom Line

Crash rated protection is the gold standard because it’s proven the hard way through real impacts, real data, and real accountability. For infrastructure owners, government agencies, and security professionals across the Middle East, that proof is what transforms steel into genuine security.

When you’re protecting critical assets or public spaces, you need more than deterrence. You need documented, defensible protection that will hold up under scrutiny and under impact.

Ready to discuss your project? Contact us at Frontier Pitts Middle East to explore certified crash rated solutions tailored to your site’s specific needs. Let’s design protection that works before risk tests it for you.