The Engineering Behind Forced Entry Resistance: Understanding the Impact of LPS 1175 RATED GATES

LPS 1175 rated gates are engineered to resist determined forced entry using real-world tool sets under defined conditions. In the UAE and Middle East, certified gate systems have become the cornerstone of high-security perimeter design—where Frontier Pitts Middle East leads as the trusted security gates manufacturer and gate barrier supplier with over 50 years of technical leadership.

What is an LPS 1175 rated gate?

LPS 1175 certified gates are independently tested perimeter security solutions designed to resist sustained forced entry using specific tools for defined periods. These systems provide quantifiable delay performance, essential for critical infrastructure and high-security sites across the UAE and Middle East.

Why LPS 1175 Matters in Modern Perimeter Security

The Loss Prevention Standard (LPS) 1175 is the global benchmark for forced entry resistance. Instead of hypothetical security claims, it delivers data-driven classifications based on how long a product withstands attack with defined tool kits.

For any serious security gates manufacturer in UAE, LPS 1175 has become a mandatory certification—especially for clients managing airports, embassies, energy facilities, and industrial assets.

Real-World Benefit:

LPS 1175 rated gates can delay intrusion attempts by up to 20 minutes, depending on the rating level, providing valuable time for detection and response.

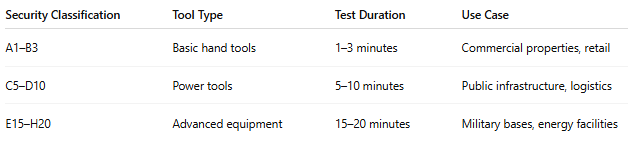

How LPS 1175 Gates Are Tested

The testing process mimics a controlled breach scenario. Trained personnel use real tools (e.g., pry bars, drills, saws) within strict timeframes to simulate what an intruder might realistically attempt.

Each rating reflects resistance—not theoretical strength, but measured, attack-tested performance.

Anatomy of an LPS 1175 Gate System

Creating a gate that survives LPS testing requires precision engineering, material science, and mechanical design.

Structural Components:

- High-tensile steel frames resist cutting, prying, and impact.

- Reinforced hinge and locking architecture distribute force and eliminate weak points.

- Hidden fasteners and anti-lift features thwart manipulation.

Material Science Enhancements:

- Heat-treated alloys with corrosion resistance

- Tool-resistant composite panels

- Anti-wear coatings for high-usage zones

Access Control Integration:

- Tamper-detection sensors

- Fail-secure electromagnetic locking

- Remote control and monitoring readiness

As a crash-rated gates supplier in UAE, Frontier Pitts also incorporates energy-absorbing structures for vehicle impact resistance where required.

Where LPS 1175 Rated Gates Deliver Real Security

⚙️ Government & Diplomatic Sites

Turnstiles like the Terra Diamond resist high-level forced entry, ensuring sensitive operations stay protected. These systems are installed across multiple UAE ministries and embassies.

🛢️ Energy and Utility Infrastructure

Oil and gas facilities demand sustained delay performance. LPS 1175 gates allow time for remote response teams to engage in case of breach attempts in isolated areas.

🛫 Airports and Transportation

Multiple zones require varying gate specifications—from staff vehicle access to restricted apron areas. Certified gates ensure compliance with both national and ICAO security regulations.

🏢 Commercial and Industrial Facilities

Data centers, logistics hubs, and industrial zones need accessibly secure gate systems. These gates balance throughput with breach resistance—essential for 24/7 operations.

Why LPS 1175 Is a UAE Standard in High-Security Projects

With rising regional threats and tightening compliance protocols, LPS 1175 has become the de facto perimeter standard across:

- Dubai’s civil aviation hubs

- ADNOC-affiliated energy facilities

- Abu Dhabi government compounds

Gate barrier suppliers in UAE must now align with both British LPCB standards and local authority approvals.

Bonus: LPS 1175 certification often leads to reduced insurance premiums and easier procurement approvals for infrastructure projects.

Future of Forced Entry Protection: Technical R&D

What’s Next in Security Gate Engineering?

- Composite materials: Deliver steel-level strength at lower weights

- Self-healing coatings: Automatically seal micro-damage

- Predictive diagnostics: Identify stress points before failure

- Biometric-compatible gates: Enabling security layering with facial recognition or fingerprint scans

Frontier Pitts invests heavily in R&D collaborations, ensuring our gate systems evolve ahead of the threat landscape.

Maintenance & Compliance: Ensuring Long-Term Certification

Maintenance Tasks That Keep Certification Valid:

- Structural inspections for weld and fastener integrity

- Lubrication of moving parts and actuator testing

- Real-time software updates for electronic locks

- Annual compliance reports for insurance and regulatory audits

A neglected gate is a failed security strategy. Regular preventive servicing extends performance and certification validity.

Making the Right Decision: How to Specify LPS 1175 Gates

Consider These Factors:

- Asset value and threat level

- Available response times

- Environmental stressors (wind, sand, seismic)

- Traffic frequency and automation needs

Partnering with an experienced security gates manufacturer in UAE ensures your system isn’t over- or under-specified.

Ready to Fortify Your Perimeter?

LPS 1175 rated gate systems are not just products—they are engineered, certified security assets designed to perform under pressure.

Frontier Pitts delivers:

- Certified gates tailored to threat levels

- Full perimeter security installation

- UAE-based technical support and servicing

- Compliance with local and international security regulations

📞 Contact Frontier Pitts Middle East UAE for a consultation or site assessment.

🌐 Visit www.fpgulf.com to learn more or book a technical demo.